Greenhouse frame: the choice of material and manufacturing features

When building a greenhouse, many questions arise. It is necessary to know from what material the frame and the coating are made, how to assemble them, and install them on the site. The review has answers to these questions and necessary recommendations.

Purpose

Greenhouse comes in different shapes. The construction is made of a rectangular type, in the form of an arch or a pyramid. The frame and the transparent coating are the two main elements that make up the greenhouse. They are made of different materials. Before installing a facility for growing vegetables and fruits, it is necessary to determine these parameters.

The frame of the greenhouse is the supporting part of the structure. It carries the main load from rain and snow. The integrity of the cultivated crop depends on the reliability of the structure. Basic requirements for the greenhouse - this building should be inexpensive and easy to assemble.

Construction can be entrusted to experienced workers or to make the building yourself.

Types of materials

The frame of the greenhouse is made mainly of plastic, wood and metal.

It is worth a closer look at each of the elements.

- Plastic profile. This modern material is durable and lightweight. It does not rot and does not give in to corrosion. The material does not require additional and complex processing. Flexible plastic is easy to give any shape. It is usually made of small-sized buildings, because it is not strong enough and bends under great weight. Light plastic frame must be securely fastened to the foundation.

- Wooden frame Frames of this material are most in demand. Wood is widely used in the construction of various structures. Material is available everywhere. The design of it turns out light and durable. In addition, the material is inexpensive. Unfortunately, wood also has disadvantages. This susceptibility to fungal diseases and rotting. The wooden frame must be treated with special antiseptics on an organic basis.Otherwise, it will emit harmful substances that adversely affect the crop.

- Metal construction. The strongest is a frame made of metal. Such basis can be all-welded or consists of separate elements. The metal frame must be installed on the foundation. Otherwise, when interacting with the ground, it will corrode. Such a structure is necessarily primed and coated with paint.

It is worth considering a few basic metals from which the frame is made.

- Galvanized profile. Zinc, although light, is not suitable for long use. It is usually used for greenhouses for one season. A year later, this metal is covered with corrosion, and then becomes brittle.

- Aluminum frame. Aluminum is a lightweight and reliable material. It provides a fortress structures and can withstand heavy loads. This metal is easily processed, which is a big plus in the manufacture of the structure. It is easy to cut and drill. All elements are easily connected with metal rivets.

- Steel construction. Steel is a strong metal. The framework turns out steady and reliable. It withstands heavy loads and bad weather conditions. But if there are no special connecting devices in its manufacture, welding works will be needed. It is desirable to coat such a structure with a special composition against corrosion.

How to choose?

First you need to decide on the type and shape of the greenhouse. There are summer and winter buildings. By configuration, they are made in the form of a house, arch, single or dual slope structures. Currently, you can buy a finished greenhouse, but it is cheaper to make it yourself. To do this, you must first select the material for construction.

Foundation of the building

The frame must be strong, reliable, withstand fluctuations in temperature, strong gusts of wind and precipitation. It is worth considering the advantages and disadvantages of materials for the profile of the building.

Plastic

This material is easy to bend and simply assemble. It is perfect for the arched shape of the building.

Plastic is characterized by the following advantages:

- the polymer bends freely;

- easy to connect with glue or tape;

- low price;

- light;

- Immune to moisture, mold and fungi;

- low thermal conductivity.

The disadvantages of the material include the following:

- it is inconvenient to fasten a film coating to it;

- cracking from temperature extremes;

- applies only to small buildings;

- hard to attach to concrete foundation.

Tree

Industrial wood in the form of larch or pine is desirable for a frame frame. Oak or beech is quite difficult to handle, because they are expensive for the price. To choose wood for a frame it is necessary without decay. Large knots, chips and cracks should be absent. Humidity of a tree - no more than 20%.

The wooden profile has such advantages as:

- low cost;

- it is convenient to mount the coating;

- simplicity in the manufacture.

The disadvantages of wood include the following:

- bends badly;

- low moisture resistance;

- subjected to rotting and fungal diseases.

Metal

The metal frame will last for many years. Even the construction of 25x25 mm profile iron pipes is able to withstand bad weather conditions.

Metal has such advantages as:

- reliability;

- not afraid of high and low temperatures;

- long service life.

Among the shortcomings of the material is the following:

- susceptibility to corrosion;

- assembly complexity;

- significant weight of the structure;

- quite high price.

Coating

Roof structures can be of several materials.

- Cellular polycarbonate is rarely used. It has disadvantages, the main of which is that the material lengthens when heated.

- In the manufacture of glass coating, too, there are difficulties. Although the material passes light well, but it is fragile, therefore, glass with a thickness of about 4 mm is usually used. This material is quite heavy, so you need the skill to work with it.

- Popular for outdoor coating film. This is a light and fairly transparent material. It is cheap, so it’s easy to get. The disadvantage is the condensate after stretching the film, formed from the inside, because of this, conditions are created for various fungal diseases that affect the cultivated culture.

Important: after weighing all the advantages and disadvantages, it is necessary to determine the materials for the manufacture of buildings.

Schemes and drawings

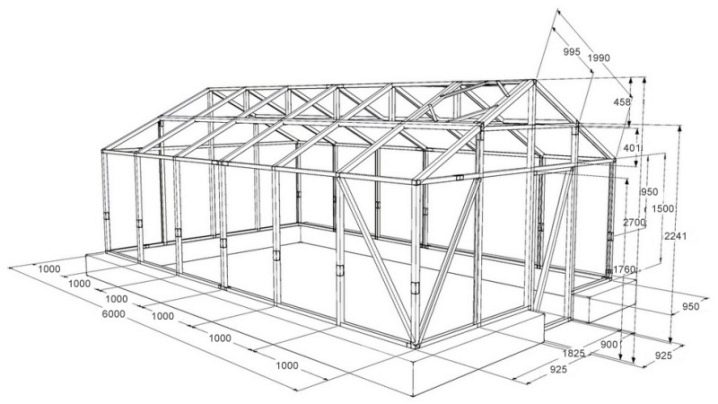

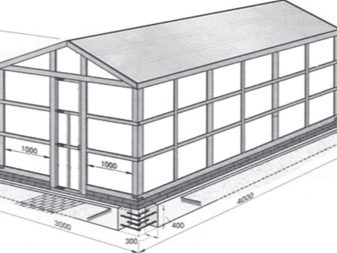

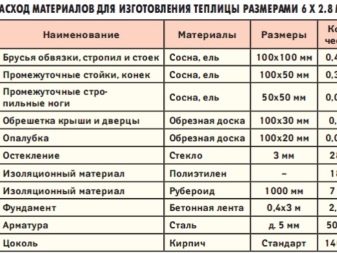

Before manufacturing, it is necessary to take into account the dimensions of the structure, as well as to calculate the amount of material required. It should make a detailed sketch of facilities. For example, it is necessary to make a drawing for a greenhouse 2 m wide and 2.3 m high. The plans include a structure with a metal frame under the film.

The drawing should contain the following frame elements:

- base;

- racks vertically;

- windows;

- a door;

- roof;

- binding;

- spacers.

The distance between the uprights is recommended to be projected up to 1 m. The gap between the roof beams should be the same size. Opposite roof bars connect. The result is a typical "farm". In places of windows and doors it is necessary to additionally mark the spacers. If the building is large, then you need to add internal metal frame amplifiers. From the profile pipe, any elements are cut, which are then folded into the desired structure.

Next, you need to calculate the amount of material needed for the coating. Polyethylene film is economically consumed with a length of two racks of about 6 m. For the width of the sleeve of the material is 3 m, and at the turn it is 6 m.When the coating is 6x6 m, so the film is consumed without waste. If the profile is made of wood, then the lower timber will have a greater thickness, in contrast to the vertical racks. When calculating the amount of material for cellular polycarbonate coating, it is necessary to take into account that the sheets are put with an overlap of 3 cm, while their usual length is 210 cm.

Assembly and installation

After drawing up the drawing and the acquisition of the required amount of material, you can begin to manufacture greenhouses. When assembling a structure with your own hands, some tools are required. A shovel, hammer, screws, screwdrivers or screwdriver, level, pencil and tape measure are required. Depending on the materials for construction, you will need scissors for metal, handsaw, nails, bolts, nuts, corners, and more. First, the project must first prepare the site. For this it is necessary to mark a place on the land. Next, you should level the ground and clean the site from debris.

The next stage is a concrete foundation for construction. It is necessary to fasten the structure on it. Along the perimeter of the marking it is necessary to dig a trench 30 cm wide and install a formwork with a height of more than 10 cm above the ground. If the frame is made of wood, it is desirable to lay roofing material on the foundation for insulation.Now it is necessary to make the base profile, which will later be mounted vertical racks. If the building is made of wood, initially you should join the lower beams with a thickness of 100 mm. The design can be strengthened by metal.

Then you should fasten the wooden racks to the sides and corners. Their thickness is about 50 mm. The same bars are suitable for the doorway. Next, you should install the eaves, ridge and door frame. Attach a profile in the middle of the roof, install the remaining elements.

Wood must be covered with antiseptic and paint.

If the frame is plastic, you can enhance its reliability. To do this, in the joints of elements, you can additionally apply adhesive tape. If the design is metal and without special fastenings, then it is necessary to weld the profile elements together. After assembly, it is necessary to process all joints with silicone sealant, which will protect moisture from ingress. Glass, polycarbonate or film coating should be attached to the fabricated profile. After that it is worth fixing minor issues.

Recommendations

When choosing a frame structure, it is necessary to proceed from one's own skills, the conditions of operation of the greenhouse and financial possibilities.

It is worth adhering to the following recommendations:

- for the summer period, you can easily build a building with a wooden frame;

- if the base is not installed on the foundation, then the lower thick parallel bars must be well anchored, secured, otherwise the structure may shift or roll over;

- it is more convenient to assemble the doorway and end elements on flat ground, after which to attach the structure to the main profile;

- if cracks appear in the wood, they should be painted over, otherwise the tree will rot from inside;

- if the building is located next to your own house, then you can make a greenhouse with a metal profile; such a building is the most reliable and will last a long time;

- plastic construction is easy to disassemble and transport to another land;

- when building a greenhouse on its own, safety precautions must be observed; if there is no experience with any tool or apparatus, then it is better to contact a specialist, otherwise the construction of the greenhouse may result in injury.

You need to think carefully about what kind of greenhouse to build and what material to make an uncomplicated and inexpensive construction.

On how to choose the frame for the greenhouse, see the following.