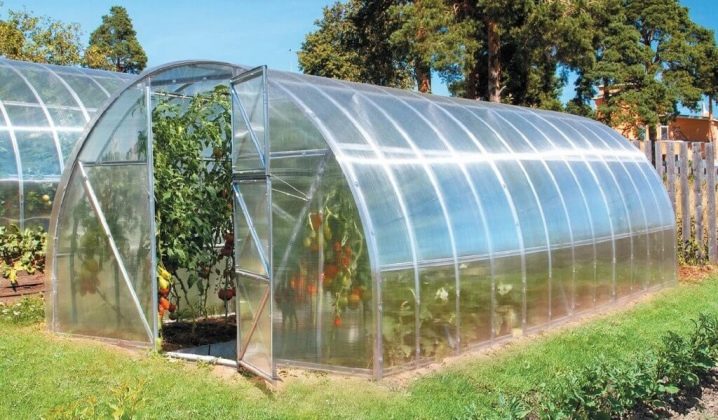

Reinforced greenhouses: what provides strength?

Growing vegetables in the Urals, in Siberia and the Far East under open ground conditions is a very difficult task. The duration of the period without frost in these regions does not exceed two months. It is impossible to grow tomatoes, potatoes, carrots and other vegetables from seeds or seedlings during this time on the open ground, so many prefer greenhouses. It is worth more detail to consider the features of such structures, how to choose them correctly, which models are in demand.

Features and benefits

The reinforced greenhouse for growing vegetables and fruits from polycarbonate protects plants from frost and bright spring sun.It withstands the pressure of one meter layer of snow and ice on the roof and gusts of wind up to 30 meters per second. It differs from simple construction by high strength and can withstand snow loads up to 820 kg / m². The arches of the ceiling are made of double metal angle or double profile, the stars on the corners are mounted on four bolts. The thickness of the bearing elements is 1.2 millimeters larger than that of a conventional greenhouse. Polycarbonate sheets of standard or double thickness are four or eight millimeters, respectively.

How to strengthen yourself?

The standard method of strengthening greenhouses is based on the hardening of their frame, which increases the resistance to wind and snow load. The simplest method is to add elements of the arched frame and longitudinal profiles. There are several budget methods for strengthening the structure of the greenhouse.

- One of them is a sticker on the sheets of polycarbonate from the inside of the long strips of wide adhesive tape. The distance between the strips should not exceed ten centimeters. When heavy snow falls, severe icing and heavy wind strengthening, the longitudinal strips help to evenly distribute the load over the entire area of the greenhouse's outer cover.

- The second method of strengthening the greenhouse is to regularly lubricate the outer surface of the polycarbonate sheets with liquid silicone or hydrophobic shoe lubricant. After that, the surface acquires water-repellent properties for several months, snow and ice do not stick to it.

- In the absence of the above components, polycarbonate can be lubricated on the outside with low-temperature (blue) antifreeze with the addition of 10% glycerol or transformer oil. Antifreeze should be applied once a week to the outer surface with a foam sponge, a rubber scraper for washing windows, a paint brush, a roller, rags and once before the cyclone, snow charge, thaw, heavy snowfall, and heavy wind.

It is worth paying attention to the generally accepted method of enhancing polycarbonate greenhouses. The standard method is the installation of additional metal arches from reinforcement, thin pipes or a corner of a square section. In the basement, large-diameter holes are drilled into which columns of five centimeters high are installed with an anchor at the end. Electric arches are welded to the posts.The basis of the design is a longitudinal channel or corner that holds the arcs together, ensuring durability. For the manufacture of reinforcing arcs can be used stainless steel, which significantly increases the strength of the structure and at the same time greatly increases its weight. The distance between the arcs should not exceed one meter.

A longitudinal carrier beam instead of a channel or a corner can be made of a pipe, by welding eyes, sprockets or other fasteners to it. According to the advice of experienced growers of the Urals and the Far East, it is recommended to make the carrying arch of polycarbonate greenhouses out of an aluminum channel or profile. This ensures the stability of the structure in gusty winds. Such an enhanced greenhouse can withstand wind gusts of 25–30 meters per second and snow pressure up to 240 kilograms per square meter.

All metal parts of the greenhouse construction must be interconnected by a copper twisted wire and reliably grounded. In the zone of increased thunderstorm activity in accordance with the EMP, on the roof of the greenhouse or near it, a linear, mesh or rod lightning conductor must be installed.At the end of the installation, the welded joints are checked with an ohmmeter, cleaned from scale and coated with a metal primer or anti-corrosion compound.

Frame

The cost of building a greenhouse and its durability directly depend on the material of the frame. The frame of the greenhouse polycarbonate should be as follows:

- have an optimal value;

- to withstand wind and snow load.

The most common for the manufacture of the frame received such materials as:

- galvanized steel;

- plastic or PVC;

- wooden beam;

- aluminum profile.

It is worth considering briefly the properties of the above materials.

Galvanized steel has the following features:

- corrosion resistance;

- ease of installation;

- low weight

Plastic and PVC have the following advantages:

- durability;

- low cost;

- ease of assembly and installation.

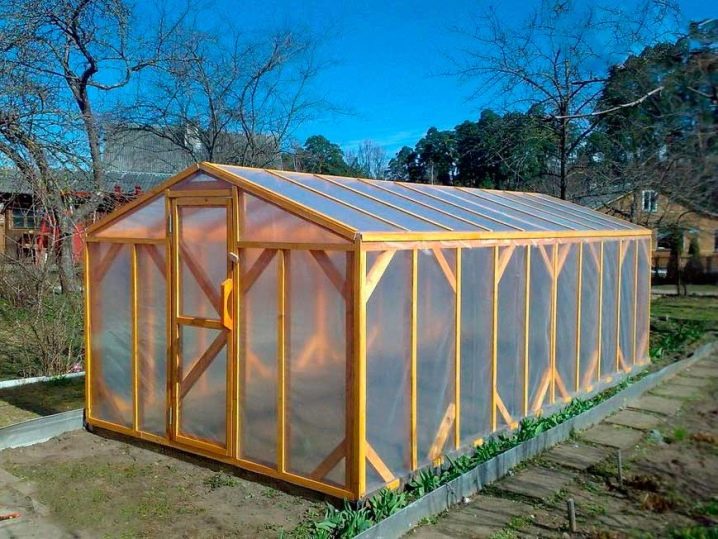

The tree has such properties as:

- ease of manufacture;

- low weight

Aluminum is often used due to features such as:

- corrosion resistance;

- ease of installation;

- can be quickly and easily transferred to a new location.

Coating

For protection against weathering greenhouse cover materials such as:

- organic glass;

- reinforced polymer film;

- cellular reinforced polycarbonate.

It is worth considering each material in more detail. Despite the appearance of plastic, organic glass continues to be used. Its physical properties are ideal for creating an ideal microclimate in greenhouses, namely:

- passes up to 94% of visible light;

- resistance to the effects of the environment;

- good thermal insulation properties;

- high mechanical strength.

Plexiglas has such disadvantages as:

- strong fastenings are required during installation;

- does not maintain hail and snow load;

- does not detain infrared radiation;

- For installation in a greenhouse, wooden, plastic or aluminum frames are needed.

If snowfalls and strong wind in the place of construction of the greenhouse are quite often - use a two-layer plexiglass coating.

In addition to conventional incandescent bulbs, in greenhouses and greenhouses install DRL type lamps as a source of ultraviolet radiation. Without them, the aphid, late blight, yeast and plant pests will multiply in the greenhouse.

Polymer film is the most popular covering material for a greenhouse and greenhouse.It is freely sold in any store. It has the following advantages:

- transmits up to 80% of light, including UV rays;

- freely transmits infrared rays;

- low price

The disadvantages include the following:

- ignites from sparks and open flames;

- condensate accumulates under the film;

- on a sunny day, condensate accumulates on the inside, on which dust and soil particles accumulate, bacteria and fungi multiply in the resulting dirt;

- the film is gradually destroyed by exposure to sunlight; the process can be slowed down if the outer surface is wiped with mineral oil once a week;

- microscopic cuts and cracks at the bend points are gradually increasing in size;

- when used outdoors, it requires full replacement in 8–10 years.

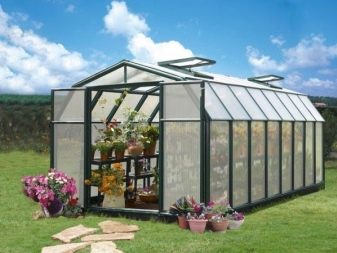

High-transparency channel or cellular polycarbonate was designed to cover greenhouses, greenhouses, and sheds. It can withstand shock wind loads and pressure of two-meter thick fallen snow. One square meter of a sheet of cellular polycarbonate has a thickness of four millimeters and weighs no more than 1.3 kg, while one square meter of organic glass of the same thickness has a weight of more than ten kilograms.Polycarbonate prevents the heat rays from escaping from the inside, which creates a “greenhouse effect”, helps to maintain an optimal microclimate inside and save on heating.

The polycarbonate surface dissipates the incident sunlight, which ensures uniform heating of the air in the greenhouse, eliminates sunburn of the leaves. With proper installation and maintenance, a greenhouse made of polycarbonate can last for 12–15 years.

How to choose ready?

Ready greenhouse made of polycarbonate with vertical straight walls - this is the best option for a backyard or cottage. Vertical walls allow you to install a greenhouse close to the wall of the house. The greenhouse cover material is a modified polycarbonate ORWO Plant, developed by the German company ORWO in 2018. ORWO together with Boeing make high-precision optics, geodetic instruments, lenses, prisms, collimators, laser instruments, portholes of the modified polycarbonate. In Russia, developed and produced analogue of this material called phytoplastic. With the passage of bright sunlight through it, its spectral composition changes due to a complex chemical reaction.

This helps to increase the yield of plants and inhibits the development of fungi and bacteria.

Assembly and equipment

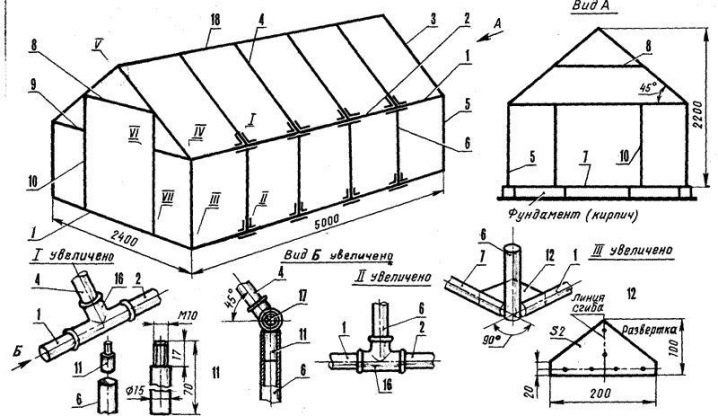

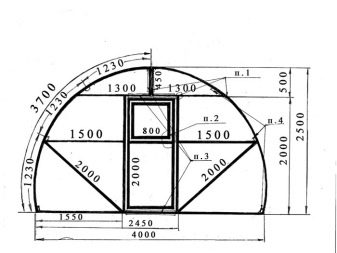

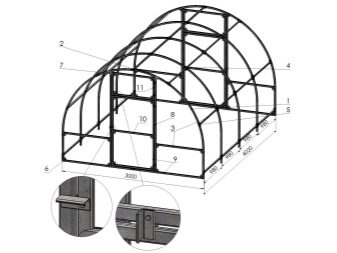

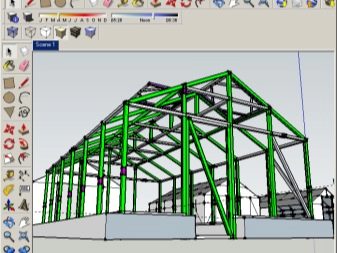

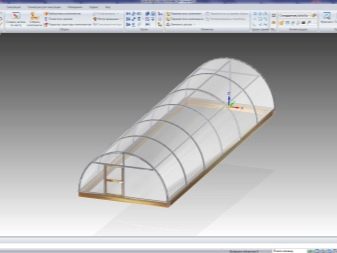

Reinforced polycarbonate greenhouse is used in areas with a harsh climate - strong winds, cyclones, snowfall. The assembly of the “home farm for growing vegetables and fruits” should be started with an assembly drawing. To do this, a little refresh in the memory of drawing and descriptive geometry. To visualize the construction of a greenhouse, you can draw an assembly drawing and isometry - a technical drawing. The assembly drawing is drawn in two projections such as:

- frontal - view from the entrance doors;

- profile view from the side of a long wall.

Building an assembly drawing includes the following steps:

- choice of scale - on each projection small details of the greenhouse must be clearly distinguishable;

- drawing external contours, drawing dimensions, fasteners, filling in the assembly specification with the name of each part according to the price list, the required quantity, GOST, retail prices;

- applying the foundation with the exact location of the pins hammered into the ground and the place of their attachment to the frame by welding;

- drawing vertical walls, rafters;

- the application of auxiliary elements of the frame, drainage systems, lintels, doors, ventilation windows and air vents;

- building in the necessary places of cuts, calculating the number of fasteners, additional materials, then the product of the final calculation of the cost of purchasing materials and their delivery.

Experts in computer technology can use AutoCAD to select the necessary parts and build an assembly drawing. When calculating the size of the greenhouse and the metal frame, it is necessary to proceed from the standard dimensions of a polycarbonate sheet - 6x2.1 meters. If necessary, the standard sheet can be cut with a grinder across into fragments measuring 3x2.1 meters or 1.5x2.1 meters. Cutting a sheet of polycarbonate in length is usually not used, because it is difficult to cut a sheet of six meters length exactly with a grinder. For the same reason, there are no polycarbonate parts in the greenhouse design with the size of 6x1.05 meters or 3x1.05 meters. For resistance to weathering, galvanized pipes and steel or aluminum profiles are used for greenhouse construction. In the front wall of the greenhouse three meters wide, the entrance doors are 2 meters high.

Browse popular models

The industry of Russia serially produces finished prefabricated greenhouses made of galvanized steel and polycarbonate, pay attention to the most popular models.

- "Uralochka" is the best option for garden and dacha plots. The armature is made of steel with a section of 20x20 millimeters. All metal parts are painted with polymer paint, which plays the role of decor. Assembly time is less than two hours. The interval between the arcs is 0.67 meters.

- "Summer Resident" includes a frame of galvanized pipe 30x20 millimeters, polycarbonate with UV protection four millimeters. The base of the construction is 3x2.1 meters, the length of the section is 2 meters, the snow load is up to 80 kg / m², the wind load is up to 15 m / s, the interval between the arcs is 0.65 m. The metal thickness is 1 millimeter.

- "Country" has a frame of galvanized profile. Its dimensions are 4x3x2.1 m, with an elongation - 6x3x2.1 m or 8x3x2.1 m; the distance between the arcs is 0.5 meters. The foundation of the greenhouse is made of wood, against rot and fungus impregnated with cyanide. The coating material is Agro polycarbonate with a density of 0.77 kg / m³ or reinforced with CarboGlass with a density of 0.8 kg / m³. Profile for the production of greenhouses - galvanized steel.Connections between parts are treated with zinc chloride.

- "Very tight." This greenhouse is made of galvanized steel. All seams between parts are treated with zinc chloride. The wooden foundation of timber for protection against fungus and pests is treated with cyanide. The thickness of the polycarbonate coating is eight millimeters. There are foundations of concrete and brickwork.

- "Optima" - it is a greenhouse made of galvanized profile 60x20 cm. From above it is covered with a sheet of polycarbonate, consists of 2–5 sections. The distance between the arcs is 90 centimeters. There are lugs for mounting reinforcing arcs.

- Leningradskaya consists of separate sections two meters long. The maximum number of sections is six. The width is three meters, the height is two meters. The foundation is a wooden beam of 100x100 millimeters. Models have flame retardant and bioprotective impregnation. A door is installed at each end. The framework is made of a profile galvanized pipe.

- "Innovator". This model is characterized by the presence of hydraulics to control the vents and automatic irrigation. This is an innovative system of fixation in the ground.

- "Family". The classic design of such a model is “Arch”.The width of the structure is three meters, the height is two meters, the distance between the arcs is 0.65 meters. The design includes two ends with doors and windows. Domestic-produced polycarbonate is four or six millimeters thick.

Reviews

Vegetable growers of the Urals, Siberia and the Far East and other regions of the Russian Federation with extreme weather conditions conducted experiments on growing tomatoes, cucumbers, radishes, dill, onions, garlic and other vegetables in modern polycarbonate greenhouses. As a result, regardless of agronomy science, they noted the following advantages:

- polycarbonate cover retains heat well;

- service life - more than eight years;

- best in the market value for money;

- if necessary, you can easily move to another place;

- protects plant leaves from burns;

- some models do not require installation on the foundation;

- can be installed close to the cottage.

But it is necessary to highlight such disadvantages as:

- relatively high price;

- polycarbonate must be protected from fire.

About what greenhouse to choose, see in the next video.