Wooden lining: varieties and trim options in the interior

Plastic and metal are often used for various finishing works, however, wooden products do not lose their relevance. As for the work on interior design, wooden lining attracts with its appearance and naturalness, and the presented range of material allows you to choose products for every taste.

Special features

Wood is considered to be the oldest building and finishing material, from which residential buildings were erected, various structures and household items were made. Over time, the tree has not lost its popularity. Today, wooden houses and wood finishes can be found quite often, even though the development of modern technologies has made it possible to obtain many different, equally durable and attractive materials.As for the finishing work inside and outside the premises, as a vivid example of the relevance of wood, you can safely distinguish products such as wall paneling.

In the present abundance of various products for cladding a house, finishing a bath or decorating a dwelling, most consumers prefer it. Even despite the existing opinion that the material has certain disadvantages, due to which the use of products in rooms with high levels of humidity, for example, in bathrooms or steam rooms, would entail damage to the material and finish.

Such concerns will be absolutely groundless, since manufacturers have taken into account these features of the raw materials, offering a large selection of various kinds of compounds, including varnishes and impregnations, to effectively solve such problems. As a rule, a protective coating is applied to products even during production. However, in most cases, cladding products are treated with fungus and insect products additionally after purchase.

In addition, taking into account the aesthetic appeal of finishing with natural material, as well as the beneficial properties of some types of wood, the advantages of the products brighten up all possible drawbacks of the products.

Lining is a cladding board, which is a product of wood processing. The life of the product is about 20 years.

The advantages of the material include the following characteristics, described below.

- Naturalness and environmental friendliness of products - the use of wood for the implementation of ideas for interior design as a result creates a unique microclimate. In addition, nutrients that are contained in conifers, have antiseptic properties, and the aroma of wood will not leave anyone indifferent.

- Due to its structure, wooden lining has a unique appearance, and the variety of wood grades used to make products allows us to offer consumers products of various colors and textures.

- The material does not belong to the category of rare products, in addition, wood panels have an affordable price.

- It is very easy to fix the clapboard due to the special tongue and groove method. This feature allows you to install even on your own without building skills.

- Products are durable.

- The material provides the bases with a reliable level of heat and sound insulation.

Like any other building products, wood panels have some drawbacks:

- Some products are susceptible to moisture, and therefore require special treatment;

- there are types of wood that have a low level of resistance to sudden temperature fluctuations;

- Products may change shape during use.

Noting the above-described cons of the products, it is worth considering that they are very uncritical, since timely and high-quality processing of the panels, as well as proper and proper fastening of the wall panel, will eliminate the risk of problematic situations with the material during use. In addition, in light of the large selection of raw materials used in the production of products for plating, you can choose the type of wood that is suitable for finishing a particular room or structure, taking into account its specific features. For example, for rooms with high humidity, such as a steam room or a bathroom, it is best to purchase a lining of coniferous varieties of wood, for rooms with a natural moisture level, larch is perfect.

Scope of application

Products are used for both exterior and interior decoration. Most often, the area of operation of products depends on the type of board.

It may be noted the main options for the use of wooden products.

- Products made of pine or spruce are recommended for finishing inside buildings. Such products can be operated at a low level of humidity, and temperatures from -5 ° C to + 30 ° C.

- The board from an alder or a linden perfectly transfers high temperatures and humidity.

- It is possible to sheathe structures outside with larch because the wood does not deform and tolerates temperature fluctuations in the range of -50 ° C to + 50 ° C, at 100% humidity level.

Such material as lining is in demand not only for arranging baths and saunas, gazebos on the plot, guest houses, verandas and terraces are sheathed with boards. Inside the house products can be found in the interior of bedrooms and living rooms, as well as kitchens and bathrooms. As for children's facilities, in such cases it is recommended to purchase products from linden, which is rich in tannins and has a beautiful shade.

Kinds

This material is divided into types based on a large number of criteria. First of all, it concerns the type of wood used for production.

There are the following categories of products.

- Lining of needles. It includes a board made of cedar, spruce, pine. Raw materials emit resin, which positively affects its resistance to external factors.

- Products from deciduous varieties: alder, ash, linden. Similar products are recommended for interior decoration. Lipa has proven itself well when decorating steam rooms, since wood practically does not heat up during operation.

- Lining of expensive varieties of wood. For its production using oak or beech. Products from this raw material belong to the category of elite building and finishing materials, which are distinguished by high cost.

Taking into account the profile of the board, the classification of products is as follows.

- Standard products - are panels with a flat base. The walls sheathed in such material are visually similar to an absolutely smooth surface.

- Softline lining - stands out with rounded corners, thanks to which the base acquires a certain texture.

- Landhouse - made with longitudinal grooves on the surface.

- American - finishing such products resembles overlapping panels. Such a system of arrangement of boards provides good protection against precipitation.

- The block house imitates the trimming of the walls with a log; the structures faced with such material resemble wooden log cabins.

- For interior decoration inside you can meet “wooden wallpaper”, which is represented in a large assortment of species.

- Lining - products differ in the size of the fasteners of the board. The products are made of high-quality materials using advanced technologies, which affects the cost of ready-to-install panels.

There are varieties of wooden products based on the class of raw materials.

- Extra-class products: for the production of products using wood that does not contain cracks, knots and some other defects.

- Class "A": lining should not have more than one knot to 1.5 meters of finished lumber. However, the board may contain cracks and resin pockets.

- Class "B": products can have no more than 4 knots per unit of measurement.

- Class "C": this category includes inexpensive products with cracks, resin pockets and other errors on the base.

Dimensions

Wooden wall paneling is of different dimensions, in addition, the size and weight of products from eurolining will be different from other types of products. As a rule, the size of products is determined by the manufacturer.

You can select the most common options.

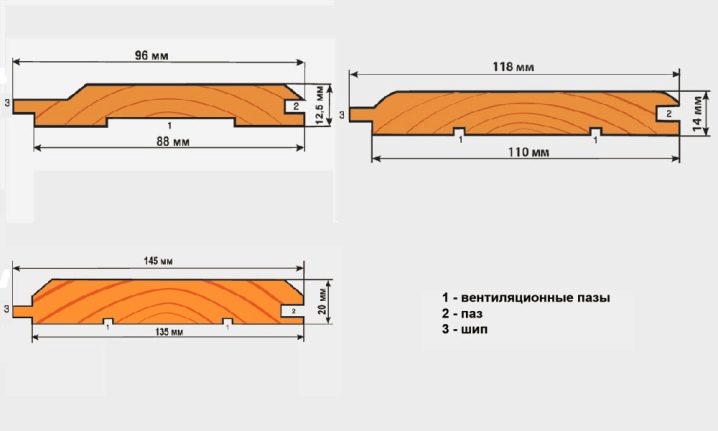

- Dimensions eurolining. The width of the products is represented by the following values: 80 mm, 100 mm, 110 mm, 120 mm, the length of the boards is 0.5-6 m, the thickness is 13 mm, 16 mm, 19 mm, and the spike has a size of 9 mm. All of the above dimensions may have tolerances of +/- 0.5-5 mm in each case.

- Other types of lining are presented in the following sizes: the width of the products varies within 76-200 mm, length - from 0.2 to 6 m, the thickness of the boards is 12-40 mm, the size of the spike is 5 mm.

Based on the length of the product, wood panels are divided into long and short. The latter type of material can be sheathed roofing overhangs or doors. In addition, small boards are much less.

Mounting technology

The process of wall cladding with clapboard includes the following work: preparation of the base, panel fasteners, finishing. The main requirement that must be considered when planning to nail any wooden clapboard to the walls is the condition of the foundations - the surface must be perfectly flat.Since in reality it will be quite difficult to find such a wall in a house or apartment, you should first take care of creating a wooden or metal frame.

Such a design can also be useful for additional thermal insulation of the room, since between the profiles and any base, be it brick or concrete, it is possible to lay heat-insulating material.

Surface plating is made by the following method.

- Installation of products can be performed both horizontally and vertically on the frame. In addition, it is often possible to find products laid with herringbone or diagonally. Fastener options are completely dependent on the preferences of the owners of the building. However, for the steam rooms you need to opt for a vertical arrangement of boards.

- Installation of lining to the crate is carried out with the help of nails, dowels or brackets, sometimes mounted on screws. For works with the ceiling, several types of fasteners are used at once, most often they are clamps and screws.

- The mount starts from the corner of the room. If klyaymery are used for mounting, then the part needs to be pushed into the groove of the wall panel, after which nails are driven into its holes.The subsequent board is installed according to a similar scheme - a new river is inserted into the groove of the previous product and secured with a kleimer.

- When mounting the material with nails or self-tapping screws, the element is hammered on the oblique into the board. After that it is necessary to disguise fasteners on the base of the wall paneling.

- Final finishing of the material involves painting or staining of wood for a harmonious combination with the interior of the room. Panels can be painted in any shade you like, ranging from white to bright and rich red or green colors.

- In addition, such a finish needs to close the edges on the lower and upper sides. To do this, use special fittings - it can be a regular plinth (fillet).

Beautiful examples in the interior

To bring an exclusive zest to the interior of the room, it is not necessary to use expensive designer materials. The wall sheathed with clapboard, different in color, size and texture, will be a real masterpiece that will decorate the room and is guaranteed to surprise guests with its originality.

For the children's room is better material than the tree is difficult to find.The ceiling lined with clapboard, unusual in its geometry, made in blue color, will visually increase the area of the room and become a bright and unusual accent in the overall style of the interior, which undoubtedly will appeal to the child.

You will learn more about the installation of wooden wall paneling in the next video.