Features of lining pine

Nowadays, finishing material called lining is gaining wide popularity. Different types of wood, both hardwood and coniferous, are used as material for manufacturing. However, the leading position still takes lining of pine, more than 50% of the market in terms of sales belong to her.

Features of wood species

For the manufacture of pine clapboard used massive board. There are several technologies for obtaining products, among which the factory version is particularly popular.

Among the natural advantages that characterize the lining of pine, can be identified:

- high mechanical strength with a small specific weight;

- the presence of natural moisture is minimal, which means that the process of drying the billet material is much faster, therefore, the cost of production decreases, and the production process is more optimized;

- the presence of resins as a preservative gives the material increased durability.

The only drawback of pine clapboard is the easy absorption of moisture and the subsequent deformation during drying. Defects will be cracks that may form in the final result.

Advantages of lining pine

It is convenient and very practical to assemble or dismantle the wall panel because of its low specific weight.

Particular attention should be paid to the fact that it does not require special formulations to protect against moisture and temperature extremes. Such products will last for many years, without being subjected to deformation and preserving the integrity of the original structure.

An important factor is considered quite low cost with a large variety.

Even the most inventive designer will be helped to choose the type he needs,because the size of the lining have many options.

One of the most important advantages can be called simplicity when fitting, if required. You can do this process yourself using a hand tool. But it will also not be difficult and skills to make the clapboard cladding.

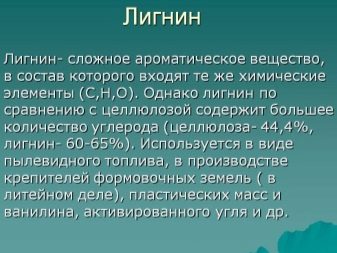

It is no secret that lignin gives the strength to a wooden product. The rate of content in the pine is 30%. We should not forget about the processing technique. Preference is given to pine because of the high resin content, which acts as an additional natural protection against moisture ingress. This criterion plays an important role in shaping the life of the finished product.

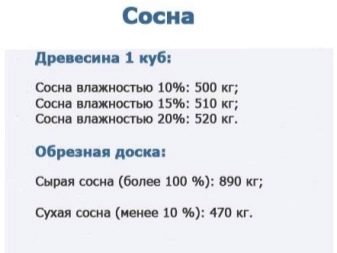

A cubic meter of clapboard made of pine weighs 500 kg in dried form and 600 kg in raw.

The weight is affected by the density of the wood.

Varieties of products

Reiki have differences in design, in size, which are inherent in the connection of elements among themselves, in the presence or absence of ventilation grooves for removing moisture, chamfers. There are such options when it is processed from two sides - it has two front sides, but there are no additional grooves.

Lining standard has received wide application, which otherwise can be called lining-quarter. These products are obtained by chamfering on the longitudinal side, and a pre-planed board is used for processing. This type is also popular among consumers due to its low cost.

The price is also influenced by the fact that raw wood is used to make the board.

The next most popular is the connection "thorn-groove", in which the pine panel is endowed with a small recess, which is obtained by machining. In the case of vertical mounting type, it is used for draining water. It is necessary to pay special attention to the fact that the moisture content of wood falls in the range from 12 to 16%. The panel has standard indicators regarding the thickness of the product, and should not exceed 16 mm. For receiving the finished board planing is applied. This option is popular due to the fact that after lining the surface is obtained, which is characterized by increased smoothness and at the same time has no seams. It has perfectly proved itself when covering both external and internal walls, including even the ceiling.

Common options are lining profiles such as block house, softline, landhouse, and American.

- Block house made in the form of rails semicircular shape, which have a special groove located on the rear surface, used to improve ventilation, and spikes on the sides to facilitate assembly.

- Softline is a board with rounded edges. The smoothness in the transition from one surface to another, at which a single spliced surface is created, gives the interior of the room a noble look.

- Landhouse - this is a plank with a width of up to 96 mm, in which the outer surface has a figured profile, and the inner surface is flat, but with additional cuts and spikes.

- American It has a special profile, which has special recesses on the inside of the board. This idea allows you to quickly make installation, and also prevents the surface from negative external influences.

Lining "Calm", which is a dried board, which has an additional chamfer, has excellent practical characteristics during finishing works.Euromodel has increased size, when compared with the standard, its width will be up to 145 mm, and the length can reach up to 6 meters. Using such panels as a finishing material, the consumer receives rooms with a refined appearance.

Often, such lining is used in residential areas, it is easy to paint.

Product classification

To purchase high-quality pine clapboard, you need to know the grade of the material used in the manufacture, which is why the division into classes occurs. There are four classes of lining: "Extra", "A", "B", "C".

Consumers who want to get the perfect interior of their premises, use clapboard from pine class "Extra"with the best feature set. It is the highest quality raw material among other classes. There are no cracks in it, and the color is uniform over the entire area. This class is considered the most prestigious, because acquiring even a cube of products, there should be no defects.

After the "Extra" class comes "A". In this wood it is possible to detect a pair of knots and special pockets from the resin, but their number will be minimal. It represents a light board, in which the quality remains at a high level.

In class “B”, three knots are allowed at a length of 1 meter of material. Pitch pockets also occur, their size should not exceed 15 cm. This class is characterized by darkening of the color, when compared with the previous two.

Rarely used as a finishing material products of the fourth class. He has a technical focus, applying to other types of work. In this class, there are options when a knot falls out and a hole is formed. As well as the standard provides for the presence on the surface of non-through cracks, the length of which should not exceed the reading of 5% relative to the entire length of the board. Pitch pockets should not exceed a width of 5 mm on a length of 50 mm.

The budget class may be accompanied by blue, but its figure should not exceed 5% of the total size of the product.

This classification allows the consumer to obtain information about the choice of class, as well as the advantages between them. The cost of m² is directly dependent on the breed used for manufacturing. Of particular value is Canadian pine, which by nature has a pinkish hue of wood color and increased smoothness,which practically leads to the absence of additional treatments.

Characteristics, size range

Currently, there are many variations in size. For example, the thickness can vary from 12 to 22 mm, but as regards the width, the following values can be found: 96, 120, 130, 145 and 195 mm. The length of the products can vary from 1.8 to 22 m.

Preferring one size or another, you must follow the rule of least waste, which will be obtained as a result of finishing.

In all cases, the price for 1 meter or m2 is indicated, and this applies regardless of the type of lining.

Recommendations before buying

A consumer who needs to purchase material for finishing a country house, a bath or a sauna, in principle, doesn’t really need to know a lot of secrets, because a quality product can be seen instantly:

- no defects;

- smooth, smooth surface of the board;

- lack of distortions;

- exact geometrical sizes.

But it is also necessary to determine the choice of the type of wood used for decoration. In the clapboard, even the edges are checked by which it is possible to determine the quality of the product as a whole.Humidity is an important criterion, so you need to constantly ensure that its indicator does not exceed values of more than 17%.

However, the drying of wood should not be allowed, because it affects the appearance of the material.

Which option is better suited for finishing baths

To give the finish a longer life, it is necessary to endow it with a certain set of properties, among which are:

- thermal conductivity;

- durability;

- opposition to moisture;

- high temperature protection;

- aesthetic indicators.

It is no secret that the bath belongs to the rooms in which temperature changes constantly occur and there is an increased value of humidity. The material can be subjected to additional coating with varnish or a special antiseptic that can protect against the appearance of fungus or mold.

Pine wood has a pleasant color as well as aroma that gives comfort. We must not forget about the healing properties with which nature has generously awarded her. It can beneficially affect the human body.

Experts do not recommend using spruce lining as a finishing material.because there is a risk to get burned from tar drops that may be exposed to temperature.

Interior finish

Wooden wall paneling is currently in high demand during the finishing work of both residential buildings and saunas, bathhouses, as well as garages. The choice of material depends on the type of room.

Pine clapboard is better suited for finishing living rooms, when compared with other wood species, but for household - linden, ash or oak are more suitable.

Facing, which will end up, allows you to comfortably influence the human body during its rest.

You can find out how to make your own hands lining up from the video below.