The details of clapboard trim

Interior decoration - the final stage of work on any construction project. The choice of the type of interior affects not only the appearance, but also the efficiency of operation of the room. Clapboard trim is a popular choice today. Consider the subtleties of finishing clapboard in our article.

Special features

Thanks to modern technology, a large number of materials have appeared that can be used for finishing and repairs. Plastic, OSB, drywall are in great demand and are used in various construction fields. However, materials from natural wood are still in demand and do not lose their positions.

The performance characteristics of the wall paneling are quite high. Natural lining non-toxic, ideal for interior cladding with versatile functions. Material is suitable both for internal works, and for external.

Options for plastic products, laminate, MDF-panels and other products are very similar to natural lining. They perfectly repeat the texture of natural wood and due to this they create an atmosphere of comfort. But still these prototypes of natural products are relevant only as an office decoration.

Of course, there are general characteristics of natural and artificial lining options. For example, the type of lining connection can be end, ridge, in “tongue”, in “quarter”. Variants of joints at the end of processing allow you to reach the finish of the seams without any connecting nodes.

The tools and equipment necessary for finishing with natural or artificial types of lining are also similar. For example, for both natural and artificial, a screwdriver with a suitable nozzle for self-tapping screws is needed. The drill of the tool in any case should correspond to the diameter of the used dowels or driven screws. They must be 60 mm long and have a dowel of 6 mm.

These products are selected based on the type of base. For example, longer nails are needed if the wall is concrete. If it is wooden, smaller screws, 5.5 mm, will be useful, for plasterboard surfaces of the product it is better to choose even less.

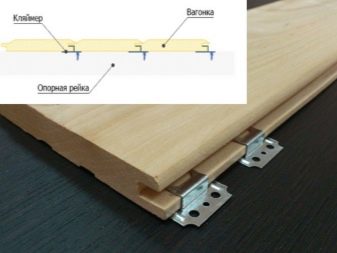

Sometimes small nails come complete with klyimery.These parts provide the installation of strap type "sheet". Another of the tools useful construction or furniture stapler. Sometimes it is most convenient for them to attach the trim parts to the crate.

A common feature is the mandatory preparation of the walls. For example, if it is brick or concrete, its antiseptic impregnation is obligatory, which will exclude the appearance of fungi. But hydroprotection for these surfaces is not needed. Often these materials are not needed for interior decoration.

Mandatory when performing both external and internal finishing works are the final elements:

- plinth;

- slopes;

- corners.

These parts are needed to hide the gaps in the joints, which always arise in the course of work. They provide an attractive and complete look to the clapboard trim. This parameter, by the way, is also related to the correct storage of the purchased goods.

Storage of any types of wall paneling is permissible only in a horizontal position and on a special stand. The room where the material is stored should not be too wet. Any products should not be outdoors. Ultraviolet adversely affects both artificial and natural materials. Before purchasing it is important to ensure the suitability of the material.This can be done by examining the packaging with the material, as well as inspecting visually. For the latter, it is important to know what characteristics a particular type of product has.

Kinds

If the whole panel is divided by signs, then can distinguish the following types of it:

- wooden;

- plastic;

- from MDF;

- aluminum.

Different types of wood are used to create wooden wall paneling. High popularity of deciduous and coniferous lining. The classification of natural finishes is associated with the grade and quality of the base, which is selected for the manufacture of the material.

The generally accepted division assumes the presence of:

- extra class;

- class "A", "B";

- class "C".

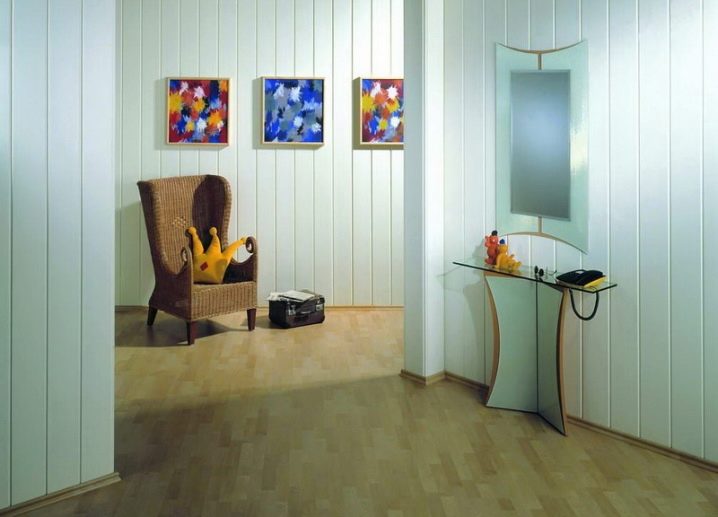

There is a difference in the material sizes. The choice of option depends on the place of application of the material. If the finishing of natural clapboard is made with high quality, it will add coziness and comfort to any room. The material is in perfect harmony with a variety of paint, wallpaper, interior items made from natural materials. Often, natural wall panels are used to emphasize certain stylistic decisions. The design perfectly combines wide and narrow lining.This material is considered both a practical and expensive choice.

Appearance of plastic lining is identical to wooden. The material used for manufacturing PVC panels is polyvinyl chloride and plasticizers. Raw materials are environmentally friendly, as evidenced by certificates. From the same raw materials are made dishes for picnics.

Standard sizes of plastic lining are identical to natural. The appearance of the finish is aesthetic. Its advantage is the variety of colors. More PVC resistant to rotting and UV light. The appearance of the coating from the front of the product is glossy or matte.

The quality of products from the coating option does not suffer. The configuration of PVC fastening products is identical to that of wooden materials. The choice of plastic lining - not an expensive solution, but the room will not be devoid of functionality.

MDF-lining is a natural species, as for its manufacture used sawdust, pressed at high temperature. Synthetic or non-natural substances products do not contain, therefore, are considered environmentally friendly.

MDF products are divided by type depending on the processing of the external part. It can be laminated, perfectly imitating natural wood. There are still veneered products. It uses valuable wood, which is subsequently painted in any shade.

There are painted products, the treated surface of which is usually shiny. This option is considered to be particularly resistant and protected from chemical influences. MDF lining can be used inside the house. This is a practical cladding material for balconies, corridors and other ancillary facilities. If the products differ in moisture-resistant characteristics, then their use in the kitchen, in the bathrooms is acceptable.

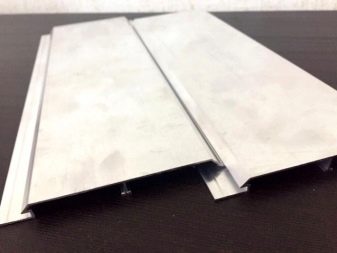

Aluminum lining has another more popular name - siding. The basis of the products is not only aluminum, but also various alloys, which include magnesium, copper, manganese. Finishing is ideal as exterior cladding of buildings and even the roof. Some varieties of material are used as inner lining.

For example, the material is resistant to moisture, so it is suitable for covering hallways, kitchens, bathrooms, balconies.The appearance of products is often an imitation of materials such as stone, wood. The characteristics of this type allow to use it even for those who have no experience in similar works. An additional advantage is the wide choice from the range presented by manufacturers. The cost of material is low, and the duration of its operational life is quite long. In addition to finishing, it is used as an independent building material.

For example, sectional fences are often made of different types of aluminum clapboard. The popularity of such fences is very big. Products are attractive in appearance, inexpensive, do not lose their beautiful appearance for a long time.

Scope of application

If we talk about wooden wall paneling, then it is more often used as a wall covering inside a log house. In an interior lining is used as decorative registration of rooms. The design with wooden clapboard can be a bright accent of terraces and balconies.

Masters providing wall cladding services claim that the fastening of wide panels is the most difficult. Yes, and designers advise to diversify the appearance of the skin, combining wide and narrow panel lining.

There are two variants of clapboard cladding:

- HorizontalSheathing is performed from the corner.

- Vertical. Fastening is performed from floor to ceiling.

If in the room where finishing works are planned, high humidity is preserved, then this is the most suitable area for the use of PVC lining. These panels are not afraid of moisture. They are also very often used as interior decoration.

There are several types of plastic wall paneling. For example, the most economical option - vinyl lining. It is suitable only for finishing from the inside. As an exterior dacha, PVC lining is suitable for exterior work. It is resistant to frost, as it contains special components.

Scope of application of MDF-lining - facing inside. This is often used material for finishing the hallway in the apartment. MDF panels, varnished - a common option for finishing the bathroom. Moisture and steam to this material are not terrible, as, however, and other negative factors.

These panels feature numerous styling options.

In addition to the vertical and horizontal location, known methods such as:

- herringbone styling;

- combined styling.

Installation of MDF-lining is possible on the walls, floor, ceiling, and other surfaces.It is undesirable to mount MDF in the bath rooms, and you should not mount them in the kitchen. But an excellent option for finishing MDF panels will be for a log house terrace, as well as a verandah of a log house.

Aluminum wall paneling is used for interior and exterior finishing. On the ceiling, they can be used with carefully insulated wiring. Aluminum is a good conductor of electricity, so even a small bare cable section will cause very great damage.

Aluminum wall paneling can also be used as wall decoration. The order of work also implies the complete insulation of electrical wiring.

If you comply with all requirements, the use of aluminum lining has the following benefits:

- profitability;

- esthetics;

- durability;

- simple care.

The operational capabilities of aluminum lining in many ways superior to other options for this type of finish. Despite the large variety of materials presented, the preparatory work that should be carried out before installation of the products are of an identical nature.

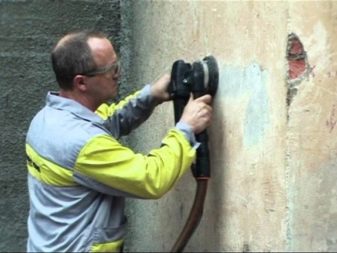

Preparatory work

Installation of panels involves the mandatory preparation of the walls. Surfaces must be dry and smooth.Sometimes a waterproofing of surfaces is required, which serves as special films or impregnations.

If there are areas with fungus and mold on the walls, an additional antiseptic treatment will be required. The more thoroughly this stage is carried out, the more protected all surfaces will be.

Under the wall paneling, it is easy to hide soundproofing or heat insulating structures - polystyrene foam or mineral plates. Also, together with a veneer material, a vapor barrier film may be required. If available, preparatory work should begin with the installation of a vapor barrier.

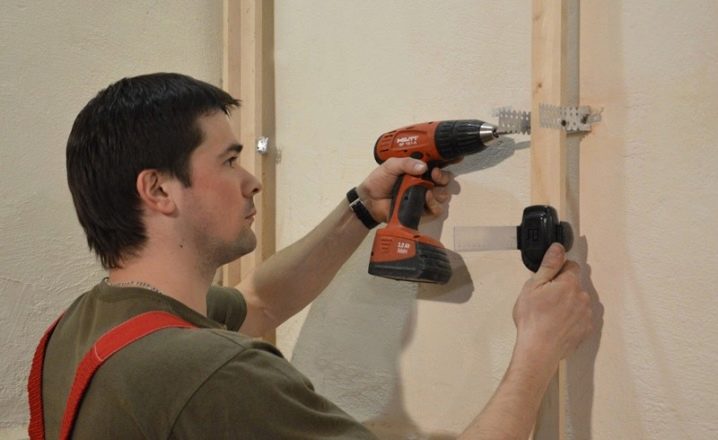

An important stage of work with any clapboard - making the frame. If a vapor barrier is needed, the selected material is overlapped directly onto the wall. A construction stapler and special staples are suitable as a retainer.

On top of the vapor barrier attachment of crates. If the laying of the wall panel is planned horizontal, then the bars should be fixed vertically, but if the wall panel is mounted vertically, then the best option for the batten is in the horizontal direction. Nails or screws are suitable as fixing parts.The best fixation of the frame installed on brick blocks will be frame dowels. At the same time mounting holes are required in the walls.

If you plan to use a vapor barrier, then it is attached to the crate also with a stapler. Waterproofing film, mounted on top of the insulator, can be reinforced with adhesive tape.

The main frame can be supplemented with another layer of crates. The second layer of bars should be fixed across the first. It is important that this surface layer of the batten is perfectly smooth, since the panels will be attached to this layer. If wooden lining is chosen, then it is worth considering its weight. The frame for this type of trim should be reliable. The desired number of bars for the frame is better to calculate in advance. This will allow not to be distracted by their production during installation of the frame.

How to sheathe your own hands?

In order to properly start fixing natural types of panels, they first need to acclimatize indoors. To this end, the wall panel is brought inside and left alone for at least two days. It is impossible to begin installation immediately, as there is a high probability of warping of cladding elements.Deformation of the structure will occur if the walls are trimmed in sub-zero temperatures and high humidity.

Installation of lining need to be made only after a fully installed crates. If you plan to install the wall panel horizontally, the first element should be mounted at the bottom, with the spike facing up. With a vertical arrangement of the slats, the installation starts from the corner farthest from the entrance to the room.

The first board must be exactly aligned with the level. It is correct to take into account both horizontal and vertical positioning of the level. Even with a small deviation of the first panel, subsequent deviations will be quite noticeable. Subsequent lining boards must first be installed in the groove of the previous ones, and then fixed with available means.

In spite of the seeming difficulties, it is possible to sheathe the walls with clapboard together with insulation and with the installation of the framework in a relatively short time. Special care will require fixing decorative parts. Corners and baseboards need to be installed with special fasteners or staples of a construction stapler. Wooden lining is additionally impregnated with wood stain and varnished.Other types of lining do not require additional processing.

A little different look work when using aluminum panels. Conventional technology involves the installation of aluminum profiles from a set of simple modules. Installation is possible with the help of small keys, which usually collect modern parts of furniture upholstered in plywood.

Despite the elementary, the developers achieve the maximum diversity and original design. Modules can be laid together with masonry. At the same time installation of modules is possible both horizontal, and vertical. Cladding is performed by sparse panels, they can also be nailed in continuous rows. Fix aluminum panels at any height. Sheathing such a ready designer is very convenient. This technology is available even for beginners.

Tips

Wooden lining seems ordinary and simple material. But the finish gets a completely different look when properly painted. The painted lining is pertinent in design interiors. This type of finish will look especially interesting with the technology of artificial aging.

If the purpose of processing is a change in color, the solution of the problem will be paint, enamel, stain. If you need to add gloss to the finish, then varnishes will be useful. If the initial material is not required to change, and the surface of the finish needs to be protected, antiseptics and flame retardants are needed. The first option is needed as a disinfectant, and the second will increase the resistance of the finish to the fire.

Decorative compositions required to change the color of the wall paneling are divided into oil and acrylate. Oil dyes form a protection and differ in the duration of the operational period. These paints penetrate the structure of the finishing material. Of the minuses, consider the resistance of the unpleasant aroma, long-term drying.

Acrylate products with no sharp odor dry quickly. Glitter and shade, they also retain for a long time. These types of coloring agents are usually more expensive than the first option. Acrylic or alkyd varnishes can change the color of the material, retaining the unique woody texture. The desired shade is achieved with the help of color schemes. Please note that the formulations can be applied only on a well-dried base.If applied to a damp base, cracks will appear on it.

The hue of the wall panel is the easiest to change the stain. However, the variant is suitable for a well-treated surface.

Lining of valuable wood is better and more advantageous will look in the frame of a transparent varnish. If there are allergies in the house, treat the base with an acrylic lacquer.

Consider the tendency of oily substances to change color after drying. Choose a color 1-2 shades darker than necessary. The most practical option for processing pine lining - painting with oily substances. Antiseptic is not required.

The selection of color is largely determined by the purpose of the room size of space. Check out the examples below. They will help determine the options for finishing and combining different types of wall paneling.

Beautiful examples

For example, if you want to add to the interior of openness, pay attention to the tinted versions of the trim in bright colors. Matt light wood will give architectural dynamics.

The interior is a good finish option can be painted products. Choose soft tones. The texture of the wall paneling will be well emphasized by the textured board on the floor.

Not bad will look attic ceiling lining. A special extravagance add aged painted finish.

No less interesting will look toning varnish. The walls and the ceiling painted in one tone - reception which was fallen in love to many designers.

If the finish is of high quality, then at any design lining will provide comfort and coziness. This is a trendy, but at the same time practical choice. The use of such cladding is possible in rooms of any functionality.

On how to make the installation of wall paneling, see the following video.